ASAP II for Postal Processing Applications

Automated CBRNe Threat Detection

ASAP II is an automated CBRNe detection and identification system for mailrooms. This customizable system can be configured to meet a customer’s exact threat deterrent needs. Typical installations include the subsystems and features described below.

Biological detection: The biothreat component of the system can be set up to detect and identify up to four bioagents. Periodically, or on demand, a concentrated wet biosample is transferred to the bio-identification system. In fifteen minutes ASAP II will identify the presence of any of the pre-selected agents, and automatically notify the operator if the mail is clear or if a pathogen has been detected.

Chemical, explosive particle, drugs of abuse, radiation: The CRNE components of the system will detect, identify and report in seconds. Expandable default libraries screen for dozens of chemical warfare agents, toxic industrial chemicals, and drugs of abuse. Radiation is detected and reported in less than one second.

Worker safety: The ASAP II system is typically housed in a negative pressure room equipped with a down draft table. An air sampling module in the system continuously samples air drawn into the downdraft table while mail is being jogged or opened over the table’s perforated top surface, providing appropriate samples to the biological identification components, while ensuring that any potential toxins are immediately drawn away from workers.

Fast, real-time processing: The ASAP II system can process thousands of pieces of mail per hour. Sampling operates continuously until processing of a batch of mail is complete, whether it is a few or several hours.

Low consumables cost: The cost of consumables in the ASAP II system is kept to a minimum by using disposable/reusable bioassay coupons that can be reused many times over a 48-hour period.

Minimal staff training: ASAP II is designed to be operated by general mailroom personnel and is fully automated, requiring little operator assistance.

Control software: Our proprietary ASAP II control software monitors all subsystems and allows the user to adjust parameters as necessary. Easy to install and use.

DOWNLOAD DATA SHEET • REQUEST QUOTE

Subsystem Features

Control SoftwareThe customizable ASAP II system can be configured with any or all of the subsystems shown here. All installed subsystems are integrated and monitored by Research International's proprietary ASAP control software.

|

Air Sampler

|

Bioidentifier

|

Chemical Detector

|

Radiation Detector

|

Explosives & Drugs of Abuse Detector

|

Typical Applications

- Clean Rooms

- Government or corporate mailrooms

- Critical infrastructure protection

- Food processing

- Homeland security

- Indoor air quality

Resources

- ASAP II System Data Sheet

- ASAP II Photo Gallery

- White Paper: "Bio-Safety in the Mail Room Using the SAMARI Negative Pressure Mail Room and ASAP II Automated Bio-Identification System"

- We offer customized seminars on ASAP II postal processing systems. Download our Postal Seminar Data Sheet, or visit our Postal Processing Seminar page.

- More information on the SASS 2300 air sampler used in the ASAP II system

- More information on the RAPTOR bioassay technology used in the ASAP II system

- More information about negative pressure mail rooms

Operational Details

In operation, the SASS 2300 air sampler (US patent 6,532,835), samples air from targeted areas continuously and transfers particulates in the air to a secondary water phase of about 4 to 5 ml volume: Aerosol sampling is performed using aerodynamically sound methods certified by fluid dynamic software models. Water samples of 1 to 2 cc are periodically transferred from the SASS 2300 to the RAPTOR. The RAPTOR then automatically performs a multi-step bioassay for up to four bio-targets on the liquid sample using a disposable assay coupon. Each of these 4-channel assay coupons may be reused from 20 to 50 times over a 36-hour unattended operating period before replacement of the coupon and related reagents is necessary. This provides extremely competitive per-assay costs and allows operation by minimally trained personnel.

The fixed-installation system includes 5-day reservoirs for wash and sampling fluids and waste water, yet weighs only 80 pounds (36 kg) and consumes an average power of 30 watts. A Windows® software package installed on a remote laptop or desktop PC allows operating personnel to monitor system and assay results in real-time and to introduce random biosamples into the workflow as needed. A large green/amber safety light connected to one of the PC's USB ports immediately communicates system status to nearby workers.

Developmental sandwich format fluoroimmunoassays are offered for ricin and anthrax. Various researchers have also demonstrated good sensitivity in a lab setting for a number of other BW agents including Francisella tularensis, Y. pestis F1 antigen, botulinium toxin, and Straphylococcus enterotoxin B. Many other pathogens and toxins may also be targeted with relative ease: contact us to discuss your needs.

OPERATING PRINCIPLES: ASAP II AIR SAMPLER

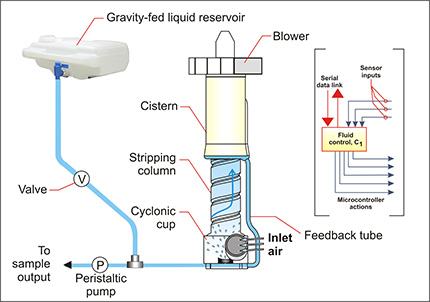

A schematic representation of the ASAP II's air sampler is shown in Figure 1. Sampled air travels through four main sections: a cyclonic cup, stripping column, cistern, and water feedback loop. A high-efficiency centrifugal blower at the sampler's exit pulls air through the unit. When operating, incoming air enters at the cyclonic cup perimeter, creating strong vortex action and a rapidly swirling film of water on exposed surfaces. This water film passes across the air inlet region, forming a water curtain through which sampled air first passes.

Figure 1: Schematic diagram of the gravity feed system of the ASAP II SASS air sampler.

Concurrently, a centrally located nozzle projecting from the cup base injects additional water. This location is subject to high air shear and fluid discharged from the nozzle into the cup forms a fine spray that is particularly useful for impingement collection of smaller particles and molecular species. The rapidly rotating air then enters a vertical stripping column where additional particulates are captured by centrifugal action: Air-water shear forces in this section create a concurrent upward flowing water film on the interior surface.

This film and the sampled air are discharged into a large diameter cistern section. Entering water is trapped and gravity-fed back into the cyclonic cup via a feedback tube and the aforementioned nozzle, while sampled air discharges through the fan. This 'pumpless' water recirculation loop will cycle a typical 4 to 5 cc fluid inventory through the unit from 6 to 20 times per minute.

Fluid Control Subsystem

Liquid inventory is monitored with a proprietary sensor attached to the water feedback tube. Water inventories may be maintained within a recommended range of about 4 cc to 5 cc with an accuracy of a few tenths of a cc, independent of temperature, relative humidity, or operating time. Samples may be removed at any point independent of ongoing air sampling, using the on-board microcontroller based peristaltic pump. A flow rate of approximately 12 cc/minute at a maximum delivery pressure of about 300 mmHg is provided. Pump power is a modest 180 mW at 12 V DC.

For more information on the SASS 2300 technology used in the ASAP II clickHERE>>

OPERATING PRINCIPLES: ASAP II BIO-IDENTIFIER

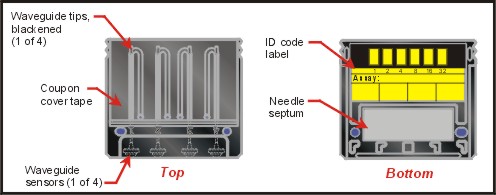

The ASAP II uses bio-identification technology that is based on the company's RAPTOR 4-channel fluorometric assay system (US patents 6,082,185 and 6,136,611). This bio-identifier can be used for high-sensitivity monitoring of biological agents, toxins, explosives, and chemical contaminants. It can automatically perform factory- or user-defined, multi-step, fluid transfer protocols while simultaneously tracking fluorescently-tagged chemical reactions occurring on the surface of each of the system's four disposable optical waveguide sensors (see Figure 2).

Each waveguide may be used to target a different pathogen or toxin, allowing the simultaneous monitoring of up to four different pathogens. The results of these assays are displayed on a four line x 16 character LCD. For the fixed-installation ASAP IIa, executive-level decisions are dictated from a desktop or laptop PC via an RS-232 link using the Windows-based user interface provided.

Figure 2: RAPTOR bioassay coupon.

Each waveguide may be used to target a different pathogen or toxin, allowing the simultaneous monitoring of up to four different pathogens. The results of these assays are displayed on a four line x 16 character LCD. The RAPTOR can also be run from a desktop PC, via an RS-232 link, using Windows-based software that is provided with the system.

USER CONTROLS/DISPLAY

PC-based control software provides user-friendly system status information and local or global network connectivity.

Specifications

Specifications for ASAP II Threat Identification System

| Parameter | Value |

|---|---|

| Use profile: | Automated/programmed/continuous identification of targeted toxins, viruses, bacteria, spores, industrial chemicals, explosives, and nuclear materials. Batch sample examination also supported. |

| Duty cycle: | Continuous. Functional availability >99.3% (1). |

| Air sampling rate: | 325 LPM |

| Bioassay profile: | Four to eight simultaneous assays performed on 1 cc samples using a credit card-size assay coupon. Coupon and associated re-useable reagents provide from 10 to 30 assays over a 24 to 48 hour use period (2). |

| Total bioassay time: | 15 to 30 minutes for collection and identification combined, is typical. |

| Bioassay sensitivity: | Dependent on analyte 1-10 ppb is typical for toxins, 3 x 104CFU/ml typ. for bacteria and spores |

| Bio-sample preparation: | None for aerosol samples, none or minimal for liquid samples; solids must be minimally extracted with buffer. |

| Toxic industrial chemicals subsystem: | Ion mobility spectrometry or long baseline infrared spectrometry. Gas libraries of 15 to 40 targets, depending on technology used. Analysis time less than 10 seconds. |

| Explosives subsystem: | Ion trap mobility spectrometer; analysis time = 8 seconds |

| Nuclear materials subsystem: | Area and portal styles available. Typical specifications: 0.05 to 3.0 MeV gamma detection window. Detect 360 kBq of Cs-137 and 6 gm Pu(2); neutron detection optional. |

| User interface: | Stand-alone or optional Windows® user interface. |

| Fluids handling: | Bi-directional peristaltic pumps. |

| Fluids storage: | 5-day supplies of buffer, disinfectant and distilled water for aerosol collector. |

| Physical size: | Usually installed as an under-counter system with video monitor on countertop. |

| Weight: | Less than 105 lbs. (68 kg) typical installation |

| Temperature range: | Operating: above freezing to 50°C; storage: -29° to 66°C. |

| Alarms: | Large green/amber status light; annunciator optional. |

| Communication: | RS-232 bi-directional serial link is standard. |

| Data storage/ programmability: | Raw/processed data storage. Operating protocols are RS-232 re-programmable. |

| Power consumption: | Less than 100 W @ 115 VAC, nominal, excluding X-ray. X-ray system requires 183-253 VAC, 50 Hz. 10 amp max. |

| Humidity: | 5% to 95%, non-condensing. |

|

Research International, Inc. reserves the right to change specifications or product source without prior notice. | |

- Functional availability is the percentage of total work time that the system is functional, averaged over a 90 calendar day period.

- Maximum usable life measured in a 25°C mailroom environment. Other applications may result in different consumable lifetimes.